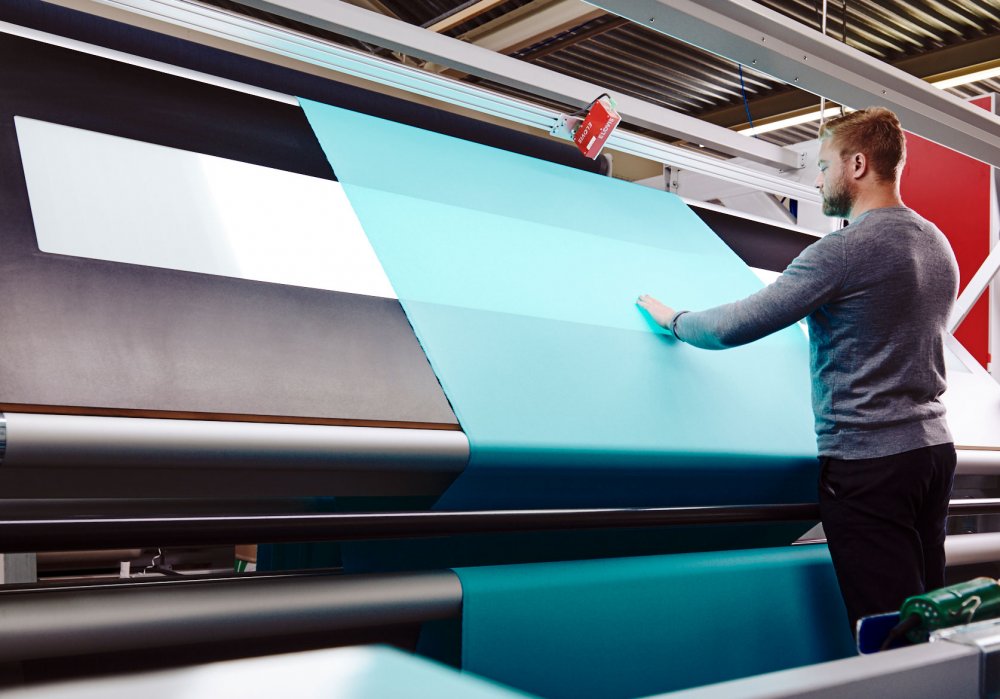

Wir nehmen an der ITMA vom 08.-14. Juni 2023 in Mailand teil. Sie finden uns am Stand H14-B304, wo wir Ihnen gerne unsere neusten Innovationen und unser Maschinensortiment vorführen.

Unter anderem zeigen wir unsere neuen Technologie-Lösungen im Bereich Warenschau und smarte Informatiklösungen. Mehr zu unseren Innovationen und Produkte-Highlights erfahren Sie zu gegebenem Zeitpunkt.

Entlang der Wertschöpfungskette in der Textilindustrie

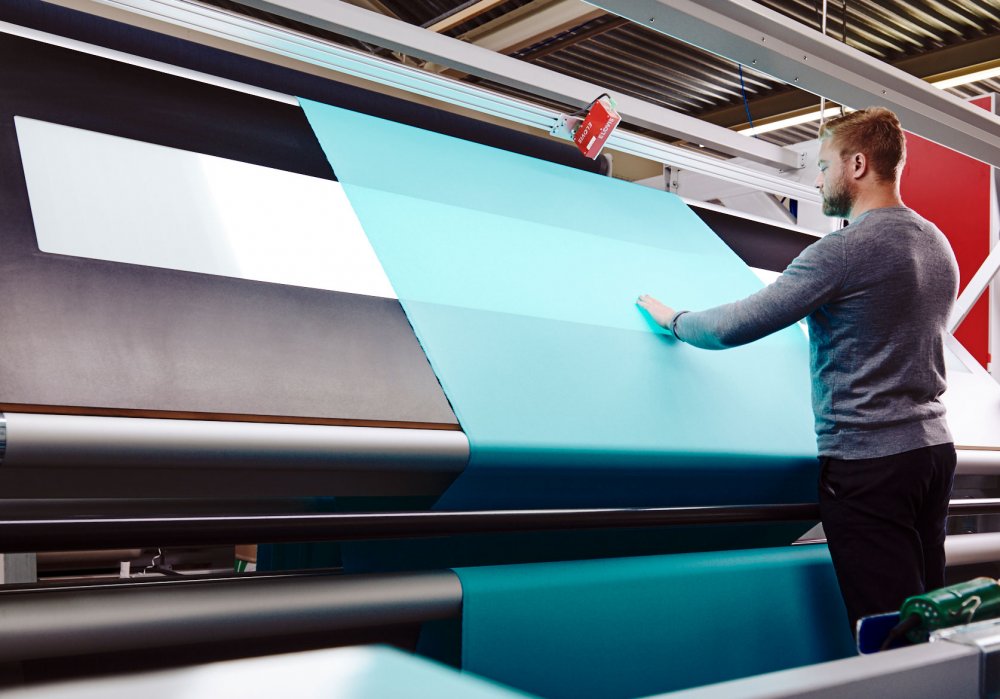

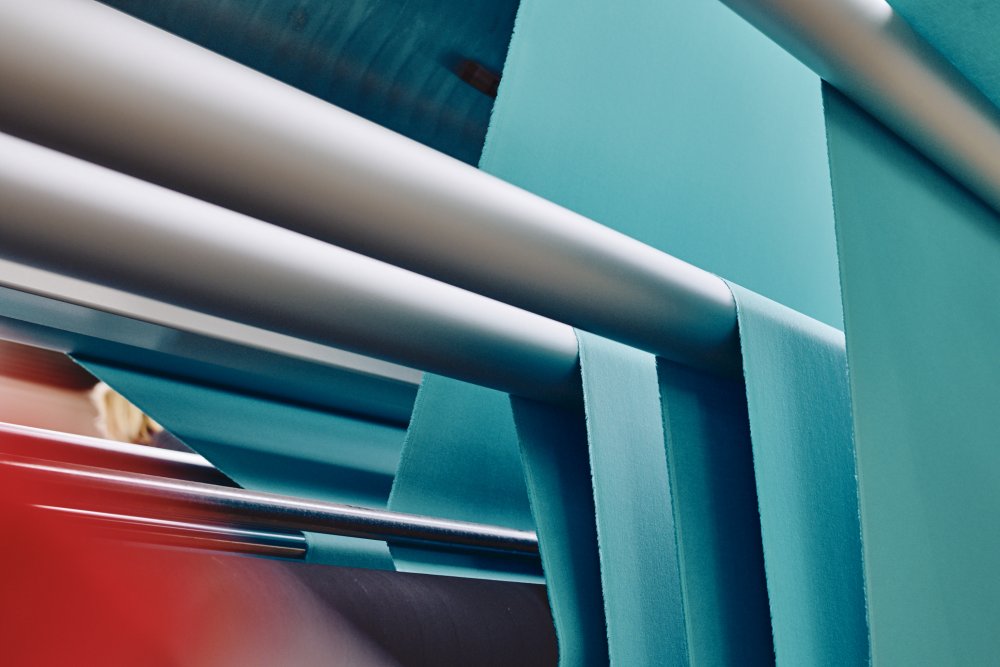

Wir sind ein weltweit führender Anbieter von hochwertigen Maschinen für die Qualitätssicherung in der Textilindustrie. Als Spezialistin für die Endaufmachung fokussieren wir uns auf die Bereiche Warenschau, Legen, Kantendruck und Verpackung.

Seit 1875 baut Maag Maschinen. Diese langjährige Erfahrung und unsere hohe Engineering-Kompetenz sind die Basis für unsere auf die Kundenbedürfnisse massgeschneiderten Maschinen und Gesamtlösungen. Maag Maschinen überzeugen durch Zuverlässigkeit, Leistungsstärke und Langlebigkeit.

Grossen Wert legen wir auf einen exzellenten, weltweiten Kundenservice und auf innovative Logistik- und Informatiklösungen.

Bei Neuprojekten beraten wir Sie umfassend bezüglich Warenschau inklusive Logistik, Verpackung, Lagerung und Datenerfassung. So können wir Ihnen eine schlüsselfertige Lösung aus einer Hand bieten.

Qualität

ein Leben lang

Walter Wespi, Geschäftsführer, Weberei Russikon AG, Russikon, Schweiz

„Zusammen mit MAAG haben wir ein Konzept für unsere Rohwarenschau und Ausrüstaufbereitung erarbeitet. Dieses Konzept umgesetzt mit Maschinen von MAAG steigert unsere Effizienz nachhaltig um 20%.“

Patric Prokein, Leiter Warenschau, Rökona Textilwerk GmbH, Tübingen, Deutschland

„Die Maschinen und die Betriebsdatenerfassung von MAAG sind in unserem Dreischichtbetrieb zuverlässig und wartungsarm. Der Service von MAAG reagiert prompt und löst Probleme innert kürzester Zeit.“

Bild: Maag Warenschaumaschine BJ 1935, immer noch im Einsatz bei der Firma Bethge in Zofingen, Schweiz